Rice milling is a process in which various methods are used to peel off part or all of the skin layer on the surface of unpolished rice. The purpose of rice milling is to partially or completely remove the skin layer of unpolished rice according to the precision requirements of different grades of finished rice.

Generally, the effect of the rice milling section can be reflected in the indicators such as accuracy, reduction rate, crushing rate, whitening rate, and bran yielding rate. Among them, accuracy is related to quality, while other indicators are related to cost, and the two are opposed to each other - the higher the processing accuracy, the more grinding, the reduction rate, the crushing rate, the bran output rate will increase, and the whitening rate will decline, resulting in a decline in economic efficiency. At the same time, the husk of rice contains a lot of nutrients, and excessive processing will lead to the loss of nutrients, resulting in waste.

White Rice with Substandard Precision

However, affected by factors such as unpolished rice moisture, waist burst rate, cortex thickness, paddy growth, harvest time and storage time, weedy rice and other factors, even the same batch of unpolished rice, the difficulty of whitening will be different. To ensure that the unpolished rice that is difficult to whiten can be whitened and the accuracy of the finished product is guaranteed, it will inevitably lead to the overprocessing of the unpolished rice that is easier to whiten, resulting in waste.

Precision Quality Sorting Reduces the Rate of Broken Rice

In response to the country's call for moderate processing and to improve the whiteness and wholeness rate of the rice milling section, Anysort solemnly launched the first intelligent sorting product applied in the rice milling section - SG Rice Color Sorter.

SG Precision Cloud Quality Sorting Machine

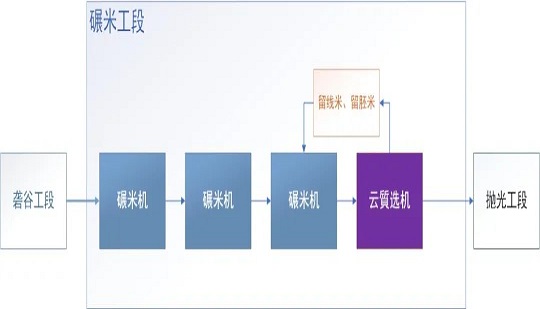

It can be installed after the rice mill to sort the white rice with insufficient milling precision and send it back to the rice mill for re-whitening. The majority of rice enterprises do not need to pressurize and whiten, which not only ensures the accuracy, but also greatly reduces the crushing rate and grinding rate of the rice milling section, ensuring the economic benefits of the majority of rice enterprises.

SG Precision Sorting Process Drawing

Anysort technology leads the future, Anysort dares to challenge, make breakthroughs and innovations, and constantly surpass itself, leading the rice processing industry to move forward in the direction of grain saving and loss reduction, and excellent grain and excellent food!