In January 2022, the "2021 China Online High-growth Consumer Market White Paper" was released. Among them, the sales of five-color unpolished rice in 2021 Taobao and Tmall increased by 494.9% year-on-year, and it was successfully sorted as a high-growth concept. Unpolished rice and red unpolished rice are the main raw materials of five-color unpolished rice. , it is also more and more sought after by the consumer market. As a result, the classification of rice products has become more and more abundant, and traditional rice processing equipment has been unable to meet the increasingly refined market demand. At the same time, the moderate processing of rice, the call for grain saving and damage reduction is getting louder and louder, and the crushing rate in the hulling section has exceeded 50% of the total crushing of the entire rice milling process. The increase of broken rice, affecting the taste and quality of rice, rice smut and various foreign matter impurities have exposed the quality risks of rice products one by one. Therefore, it is very necessary to do paddy and unpolished rice sorting in the grain hulling section.

For the function of paddy and unpolished rice sorting, you can refer to our previous article "Paddy and Unpolished Rice Quality Sorting Will Save Grain and Reduce Losses to Tens of Millions of Grain Enterprises", whether it is red unpolished rice to meet market demand, or to reduce the breakage rate of the grain hulling section , and paddy and unpolished rice sorting can provide scientific solutions. Today, I will introduce the new paddy and unpolished rice sorting process extended after the advent of the Anysort SF cloud sorting machine.

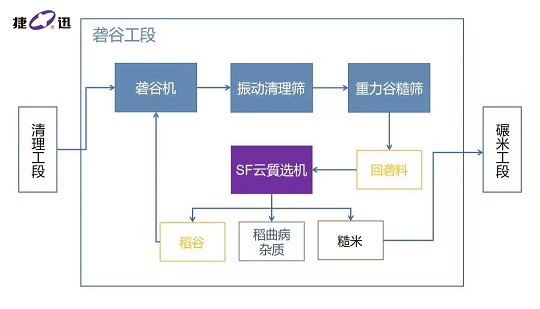

Quality Sorting Process of Back-hulling Material

According to the survey, the content of unpolished rice in the husked material returned by gravity rough sieving is between 30% and 70%, which will cause a large amount of unpolished rice to return to the grain hulling machine for secondary extrusion, which is easy to produce rough and broken grains. The main purpose of the quality sorting process of the back-hulling material is to reduce the unpolished rice content in the back-hulling material, thereby reducing the broken rate and the broken grain rate of the rice in the hulling section.

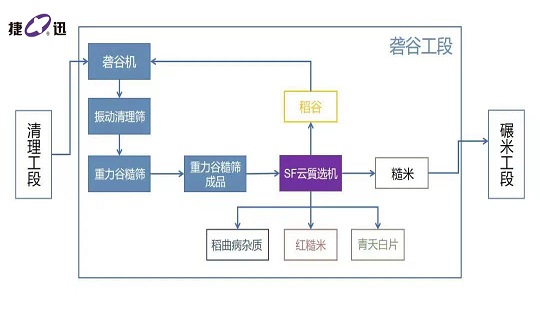

Unpolished Rice Quality Sorting Process

The unpolished rice quality sorting process is mainly to classify the finished products of the gravity paddy and unpolished rice sieve by the Anysort SF cloud color sorter. The SF cloud color sorter can sort the red unpolished rice, silty qingyao white flakes, paddy, and impurities to ensure the quality of unpolished rice in the rice machine.

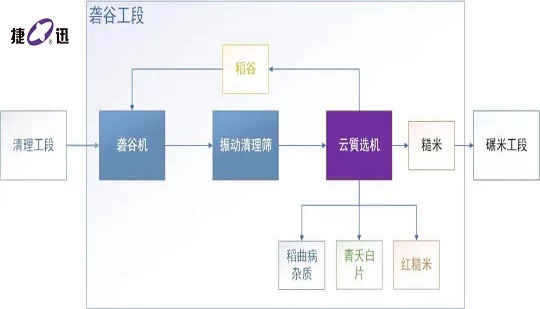

Material Sorting Process Under Hulling

The hulling material sorting process is a process of directly replacing the traditional grain separation equipment and unpolished rice sorting equipment with the SF cloud color sorter. Sorting of rice smut grains, foreign matter impurities and other materials. This process has all the advantages of the above two processes, and at the same time, it can also realize the digital analysis and output of the grain hulling machine and the lower grain rough mixture. It is the core process of paddy and unpolished rice sorting.

The above is the paddy and unpolished rice sorting process of Anysort SF cloud color sorting machine. They realize more detailed and humanized rice processing, make rice products more abundant, allow moderate processing, grain saving and loss reduction can be realized. The process of paddy and unpolished rice sorting is also waiting for you to explore with us.